The Leander pilot is supposed to begin in operation in June.

Mr. Sims was guarded in addressing details about the organisms. He said that they were based on what occurred in nature that and each type would secrete a different chemical.

The cells will eat, reproduce and then sweat; water flowing through the system will carry off the hydrocarbon fuel for separation, he said.

After about eight weeks, workers will flush the system clean and start over with a new batch, he said.

Carbon dioxide is trucked in for now, but the longer-term strategy is to locate the operation near a power plant that runs on coal or natural gas and captures its carbon dioxide. If a national cap on emissions is enacted, a power plant might be willing to pay a fuel plant to take its carbon dioxide gas.

Another potential source is a conventional corn ethanol plant, which produces a pure stream of carbon dioxide.

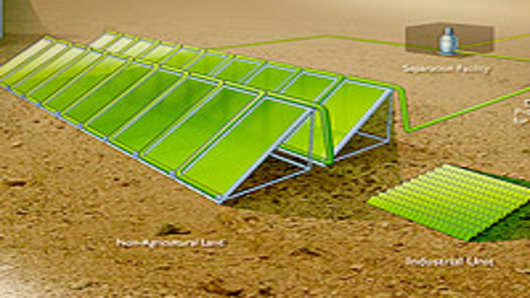

Last week Joule said it had raised $30 million in a second round of financing. The scale-up from the demonstration plant is simple, Mr. Sims said: just reproduce the cluster of panels, the piping that connects them and the separation plant.

The company projects production of 25,000 gallons of ethanol a year from each acre, which would be many times higher than production from wood waste or other biomass source.

Of course all of this remains to be demonstrated, but Joule hopes to be in commercial production in 2012.