Hundreds of miles from the epicenter of "deflategate," it's still business as usual at the Wilson Football Factory, located in the small town of Ada, Ohio.

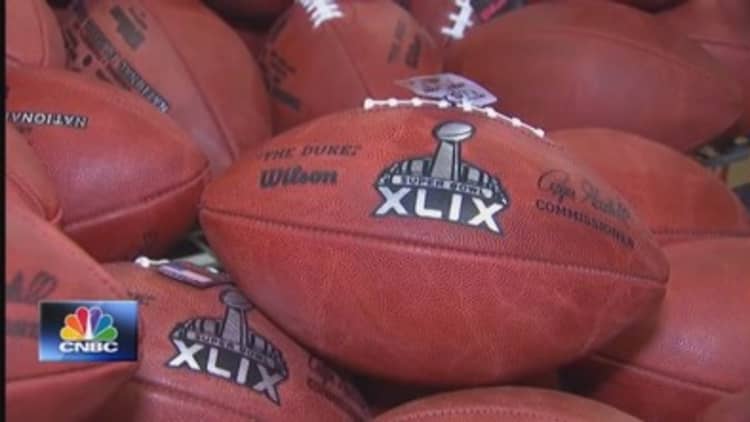

More than 130 workers are tirelessly cutting, stitching, lacing and sewing 3,000 footballs per day and preparing for their biggest day of the year—Super Bowl XLIX—when the fruits of their labor take the world stage.

"My proudest moment every year is when they kick that Super Bowl off. The focus on that ball being kicked off, and to know that football came from Ada, Ohio, and it was made by our people is just a great feeling," said Dan Riegle, Wilson Football plant manager.

Read MoreSuper Bowl ticket prices blowing out records

The Wilson factory is a rare sight in an era of automation and outsourcing. Located 70 miles from Toledo, Ohio, the Ada factory was opened in the 1930s by the Ohio-Kentucky Manufacturing Co. The firm produced footballs, baseball gloves and boxing gloves. In 1955, Wilson purchased the company and decided to focus solely on footballs.

Today, the factory churns out every football used in the NFL and NCAA college football as both leagues' official partners. Creating 700,000 footballs per year, Wilson controls about 70 percent of the market, with the NFL its longest-running and most lucrative partner.

"Since 1941, every point scored in the NFL has been with a Wilson football. We are very proud of that relationship and want that to continue. We try and make the best-quality product in the world for them," said Riegle.

From leather to laces, Wilson's football is 100 percent American-made. The plant's workers don't use high-tech equipment; instead, they use sewing machines from the mid-1900s, and they stitch the footballs' lacings completely by hand.

Many plant workers have been with the company for generations.

Read More What players get paid for winning the Super Bowl

"Our plant average is 20 years seniority. If you sew footballs, you do it every day of the year. If you do it for 20 years or 10 years or five years, that's what you specialize in. That's your job and you are going to make a more quality-oriented, consistent product," said Riegle.

From start to finish, a football takes approximately three days to make. The process of making a ball begins with a cowhide. Wilson buys 15,000-20,000 feet of cowhide per week, which comes from Horween, a leather company in Chicago. One cowhide can produce as many as 20 footballs, but a drought two years ago has created a shortage of cattle and meant higher leather prices for companies like Wilson.

"Leather's price has trended up for the last couple of years. Hopefully we will get that cow herd built back up, and we'll be able to flatten out the price and get the price of leather back down, which effects my cost obviously," said Riegle.

From farm to factory, the hide is then cut into oval panels which will eventually be sewn together to make the body of the ball. To maintain its shape, a liner is sewn inside the ball as well as a bladder for inflation. From there, the balls are sewn together, stamped with logos, hand-laced and inspected thoroughly.

It's a multistep process that has been perfected over decades, but often it's a race against the clock to produce footballs in time for the big game.

"We were all here for the conference championship on a Sunday and as soon as we knew who was going to be on the Super Bowl, we immediately began stamping Seattle and New England on the balls. We worked around the clock to get the production of the Super Bowl balls all out," said Riegel.

Read MoreSuper Bowl: How to get there, and how to get in

Each team will receive 54 balls for the Super Bowl, and then Wilson makes about 10,000 commemorative balls for fans.

"At some point during the game, several times probably, you say we made that ball, we made that ball. You do keep your eye on that ball a little more than if you were just a fan," said Riegel.

As for the recent controversy involving the New England Patriots allegedly using deflated footballs in their conference championship defeat of the Colts, Wilson says that every one of its footballs is inspected, weighed and measured, and falls within NFL guidelines.

"Our job here as far as manufacturing footballs is to know that when a ball leaves here, it has 13 pounds of air pressure in it. After it leaves the building, it's out of our control," he said.

Disclosure: CNBC's sister company NBC Sports broadcasts the Super Bowl.