Levi's is replacing its workers with lasers, automating the process of making blue jeans look worn out.

When you buy a pair of distressed denim jeans, there is a lot of manual processing that goes into creating that look. After the fabric is stitched together, workers use harsh chemicals and sanders to add that final shabby look to the fabric.

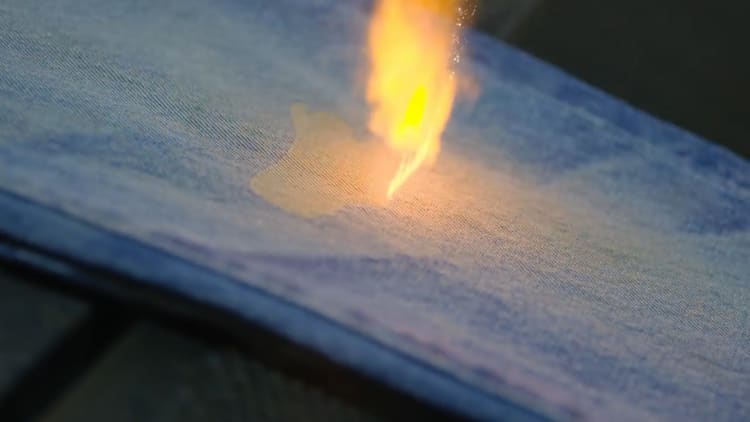

Levi's has turned to technology to make the process faster and more environmentally friendly. Project F.L.X. (future-led execution), as the new machines are called, uses infrared light to etch off a fine layer of cotton and color from jeans in seconds. While the previous process would typically have taken 20 to 30 minutes per pair of jeans, laser finishing takes just 90 seconds to get the same result.

This new process will also reduce the number of harsh chemical compounds Levi's uses in its process. Currently, the company says it uses a few thousand chemical formulations, which project F.L.X. would reduce to just a few dozen. Levi's calls this is a major step for the company in its pledge to remove all hazardous chemicals from its manufacturing by 2020.