In March, Arash Malek was "sheltering in place" in California and looking for a way to help during the COVID-19 coronavirus outbreak.

So he turned to the laser cutter in his garage.

Malek is the founder of a company that sells custom air fresheners for Teslas, and he figured he might be able to use his fabrication skills to help with the protective personal equipment, or PPE, shortages that are putting medical professionals and patients at risk.

A respiratory therapist he knew through the Tesla community said he could help Malek create a design that medical pros could use. After he gave the green light, Malek produced 2,500 face shields, and shipped the first boxes this week to hospitals that have asked for donations, including Children's National in Washington, D.C. He's put his business on the back burner for the moment to focus on PPE.

"I had an epiphany, if our health-care workers start reducing in number it's going to be catastrophic for everyone," Malek said. "I realized I could have greater impact if I focused on the health-care pros on the frontline."

Individual makers and small groups are mobilizing during this crisis because of a dire lack of PPE across the country, which has waves of doctors and nurses asking for help.

In California, officials stockpiled 21 million face masks for emergencies, but many of them were expired. California distributed the masks to frontline medical workers anyway. In New York City, the center of the outbreak in the United States, Mayor Bill DeBlasio said this week that New York has only enough N95 masks to last through the end of the week. The federal government is asking agencies that might have stashes of spare medical supplies to redistribute them to hospital staffs and emergency responders as the national stockpile runs low.

Hospitals and governments have set up websites to take donations of PPE from the public, often asking for face shields specifically in addition to masks and gloves. Arash has an intake form on his website and he says he has been surprised by the number of medical workers asking for face shields.

Face shields are gaining favor because they use materials that are easy to obtain and can be made quickly. At its most basic, a face shield is a piece of clear, non-porous plastic to protect health workers' faces from coming into direct contact with saliva droplets that may contain the virus.

Face shields are supposed to be worn in conjunction with other PPE, like surgical or N95 masks, and can make them last longer. That means the shields don't need to be made to strict medical-grade specifications.

"The overall specifications to build those are not going to be as stringent as a face mask or respirator," said Dr. Sanjay Kurani, medical director at Santa Clara Valley Medical Center.

Up to 30 sets of PPE per patient, per day

Santa Clara Valley Medical Center worked with a Sunnyvale, California, nonprofit called Maker Nexus to create a face shield design that can be used at the hospital and reproduced in large quantities. The supplies are critical given that one COVID-19 patient might require doctors and nurses to use 30 sets of PPE per day on that patient alone, Kurani said.

Santa Clara County in California was one of the first places in the U.S. to report community-spread coronavirus cases, and it's been watching its PPE supplies closely. It's under a shelter-in-place order until May 3 and there are currently 277 hospitalized patients in the county that are diagnosed with or suspected to have COVID-19.

The hospital has an infection prevention team evaluating PPE donations, and the staff appreciates the help.

"It has surprised us to the point where people are almost in tears that there are others supporting us and what's happening while we're socially distancing," Kurani said. "To feel connected to the community this way is a huge morale booster."

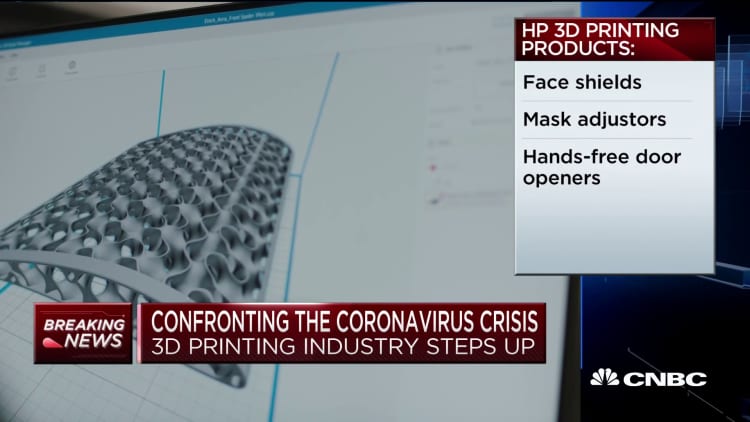

Maker Nexus typically provides machining tools for its members to fabricate new prototypes, but under shelter-in-place they're using 3D-printing to produce face masks, and making the design public. Maker Nexus cofounder Jim Schrempp said that the effort from people with fabrication skills reminded him of WWII-era "victory gardens," when the government encouraged people to grow their own food to help with supply.

"Demand for PPE has ballooned, and the response is happening all over maker spaces," Schrempp said, adding that if demand for face shields falls because there's enough supply, there are additional ideas and requests for PPE that the organization would love to make.

Getting help from medical professionals to optimize the face shields is a critical step in the process. Schrempp said that their design went through seven or eight iterations to make it safer, including lengthening the shield, limiting attachment points, and adding a top covering.

Organizations with greater capacity are mobilizing, too. Gustavo Fontana, an industrial designer who cofounded Fresco Design, said that he's been working with a group called Ushield, which has found a factory in the Northeast that can produce as many as 100,000 face shields per day from readily available plastic. His first "pilot run" shipment of 4,200 shields went out to hospitals across the country this week.

"Every day you can get an extra shield faster to a worker, it's potentially lifesaving for that person," Fontana said.

Now, big firms with corporate expertise in supply chains and manufacturing are getting involved making face shields as well. Apple is making 1 million face shields per week, and its design comes with professionally made usage guidelines and assembly directions. Ford has donated face shields to Michigan hospitals as well as the New York police and fire departments. Nike is using materials originally intended for sneakers in its face shield design that's being shipped to hospitals in Oregon.

The little guys don't mind the big companies joining in on the mobilization effort — to them, the point is to help out the health-care workers on the frontlines who are fighting the outbreak and incurring personal risk. In fact, many makers said, expensive techniques available to big firms such as injection molding could result in better shields at a large scale.

"People are expecting big companies like Apple to step up, and that's great, but collectively we're all in this together and everyone can do something," Malek said.